Reliability Test

Ching Mei Optics conducts multiple reliability tests in-house to ensure our coating quality, including:

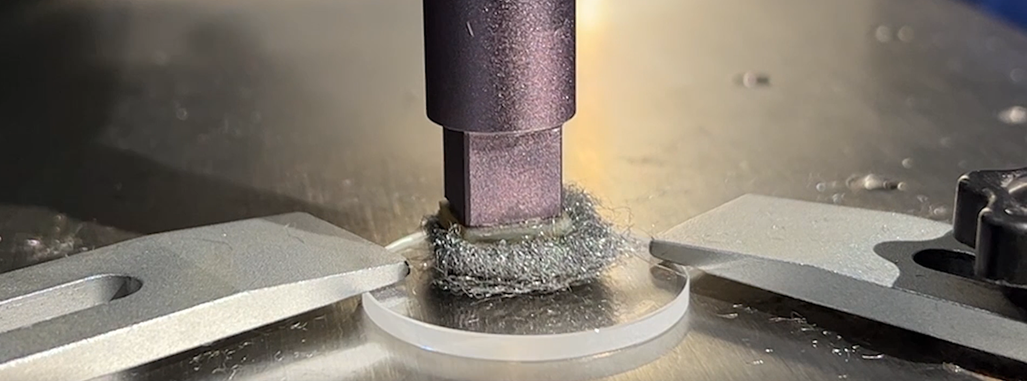

Steel Wool Durability / Abrasion Test

The Steel Wool Durability or Abrasion Test is a method used to assess the resistance of a surface or material to wear and abrasion. This test involves the use of steel wool, a bundle of fine steel filaments, to simulate the abrasive actions that a surface may experience during normal use or under specific conditions. It helps in assessing the durability and longevity of products and surfaces, ensuring they meet quality standards and can perform satisfactorily over their intended lifespan.

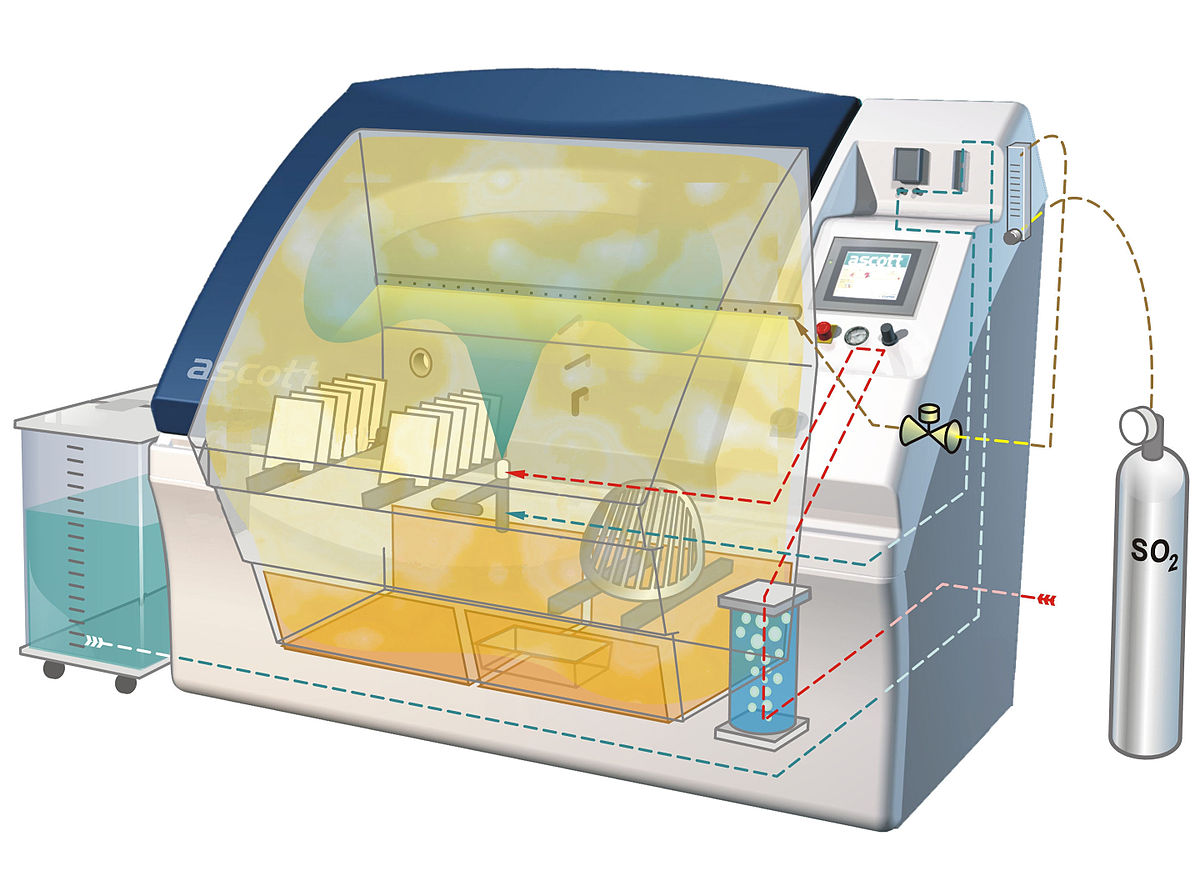

Salt Spray Test

Salt spray testing is a widely used testing method for watch glass. This test aims to simulate the durability and performance of watch glass under extreme environmental conditions. It typically involves spraying a saltwater solution on the surface of the watch glass and exposing it to high-temperature and high-humidity conditions to assess the glass’s corrosion resistance and oxidation resistance.

One of the main advantages of this test is its ability to quickly and accurately assess the quality and durability of watch glass. By observing the impact of the saltwater solution on the glass, we can determine whether it is susceptible to corrosion or discoloration and whether it can maintain clarity and appearance quality.

Salt spray testing also helps ensure that watch glass maintains superior performance and appearance quality in various environments. It ensures that the watch is not damaged when exposed to water, sweat, saltwater, or other humid conditions, thereby extending the watch’s lifespan.

Artificial Sweat Test

The artificial sweat test applied to watch glass aims to simulate the conditions that a watch encounters during daily wear, especially when it comes into contact with skin and is exposed to sweat. By applying artificial sweat to the surface of the watch glass, its tolerance and performance under these conditions can be assessed. During the test, samples are exposed to a synthetic solution that simulates human sweat. This solution typically contains various components such as salt, acids, and proteins. Samples are subjected to controlled conditions, including temperature and humidity, to mimic real-world scenarios. This evaluates whether the watch glass can resist the effects of substances like sweat and sebum, maintaining clarity and appearance quality. This is crucial for the everyday use of watch glass, as it frequently comes into contact with sweat from the skin.

The artificial sweat test applied to watch glass aims to simulate the conditions that a watch encounters during daily wear, especially when it comes into contact with skin and is exposed to sweat. By applying artificial sweat to the surface of the watch glass, its tolerance and performance under these conditions can be assessed. During the test, samples are exposed to a synthetic solution that simulates human sweat. This solution typically contains various components such as salt, acids, and proteins. Samples are subjected to controlled conditions, including temperature and humidity, to mimic real-world scenarios. This evaluates whether the watch glass can resist the effects of substances like sweat and sebum, maintaining clarity and appearance quality. This is crucial for the everyday use of watch glass, as it frequently comes into contact with sweat from the skin.